Essential Maintenance Tips for Butterfly Valves

Mar 15, 2024

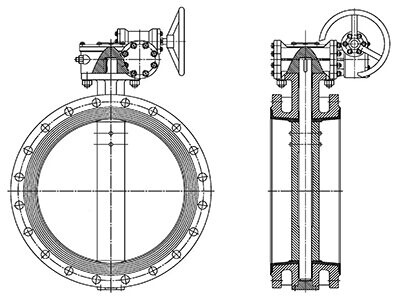

Butterfly valves play a vital role in industrial pipelines by regulating fluid flow with their simple yet efficient design. However, over time and with changing conditions, they can develop issues like wear and leakage, impacting their operation. To ensure industrial production continuity and stability, maintaining and servicing butterfly valves is crucial. This article discusses maintenance measures to extend their lifespan, improve efficiency, and support reliable production.

1. Pipeline and Valve Passage Cleaning

First and foremost, regular cleaning of pipeline and valve body passages is essential. This prevents iron filings and other debris from entering the valve body, thereby affecting the valve's normal operation. Cleaning should be done with water to ensure thorough removal of residues, especially considering frequent valve opening and closing, which is particularly crucial.

2. Safe Valve Shutdown and Pressure Release

Before performing maintenance on butterfly valves, it's imperative to ensure the safe shutdown of valves and complete release of pressure from within the valve body. For electric or pneumatic butterfly valves, power and air sources should be disconnected first to ensure operational safety. This helps avoid accidents during maintenance and ensures the safety of personnel.

3. Sealing Material Handling

Both soft-sealed and hard-sealed butterfly valves require careful handling of sealing materials. When disassembling valves for cleaning or repair, caution must be exercised to prevent damaging the sealing ring and causing leaks. For hard-sealed butterfly valves, where the sealing surface is typically metal-welded, attention to detail is crucial during operation to prevent damage to the sealing surface.

4. Appropriate Cleaning Methods

For pneumatic butterfly valves, solvent selection for cleaning should avoid conflict or corrosion with valve components. After cleaning, solvent residues should be thoroughly evaporated, ensuring complete removal of all residues. If cleaning with water alone proves insufficient, targeted cleaning with alcohol or similar solvents may be necessary.

5. Addressing Leakage Issues

When minor leaks are detected at packing locations, it's important not to overtighten the valve stem nut but to tighten it moderately until the leakage stops. Overtightening can damage the packing and exacerbate leakage issues.

6. Proper Valve Storage

Long-term outdoor storage can lead to valve corrosion, significantly affecting its lifespan. Therefore, measures must be taken to protect valves from rain, water, and moisture, with flange covers tightly secured in place. If storage exceeds 12 months, retesting before use is necessary to ensure stable performance.

First and foremost, regular cleaning of pipeline and valve body passages is essential. This prevents iron filings and other debris from entering the valve body, thereby affecting the valve's normal operation. Cleaning should be done with water to ensure thorough removal of residues, especially considering frequent valve opening and closing, which is particularly crucial.

2. Safe Valve Shutdown and Pressure Release

Before performing maintenance on butterfly valves, it's imperative to ensure the safe shutdown of valves and complete release of pressure from within the valve body. For electric or pneumatic butterfly valves, power and air sources should be disconnected first to ensure operational safety. This helps avoid accidents during maintenance and ensures the safety of personnel.

3. Sealing Material Handling

Both soft-sealed and hard-sealed butterfly valves require careful handling of sealing materials. When disassembling valves for cleaning or repair, caution must be exercised to prevent damaging the sealing ring and causing leaks. For hard-sealed butterfly valves, where the sealing surface is typically metal-welded, attention to detail is crucial during operation to prevent damage to the sealing surface.

4. Appropriate Cleaning Methods

For pneumatic butterfly valves, solvent selection for cleaning should avoid conflict or corrosion with valve components. After cleaning, solvent residues should be thoroughly evaporated, ensuring complete removal of all residues. If cleaning with water alone proves insufficient, targeted cleaning with alcohol or similar solvents may be necessary.

5. Addressing Leakage Issues

When minor leaks are detected at packing locations, it's important not to overtighten the valve stem nut but to tighten it moderately until the leakage stops. Overtightening can damage the packing and exacerbate leakage issues.

6. Proper Valve Storage

Long-term outdoor storage can lead to valve corrosion, significantly affecting its lifespan. Therefore, measures must be taken to protect valves from rain, water, and moisture, with flange covers tightly secured in place. If storage exceeds 12 months, retesting before use is necessary to ensure stable performance.

Through the implementation of the above maintenance measures, we can effectively prolong the lifespan of butterfly valves, enhance operational efficiency, reduce replacement costs, and ensure the smooth progress of industrial production. Regular maintenance not only saves on repair costs but also improves equipment reliability and stability, serving as a safeguard for business development.

Next: Technical Features of High Performance Butterfly Valves

Previous: Optimization and Maintenance Guide for Wafer Butterfly Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China