Understand Principle and Key Features of Top-entry Ball Valves

Mar 23, 2024

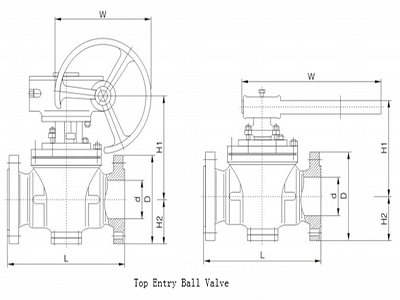

Top-entry ball valves, as a common and essential type of valve, play a crucial role in the industrial sector. Their simple structure and excellent sealing performance enable the control of fluid flow by rotating the ball. This article delves into the working principle and major advantages of top-entry ball valves in industrial production.

Working Principles

Top-entry ball valves control the flow of fluid by rotating a ball. When the valve is closed, the ball tightly seals against the valve seat, ensured by spring force or medium pressure. Opening the valve involves rotating the valve stem to move the ball away from the seat, allowing smooth fluid flow. Closing the valve causes the ball to reseat, achieving a seal.

Major Advantages

Top entry ball valves offer several advantages over other types of valves, such as side entry or split body ball valves. Here are some key advantages:

- High Sealing Integrity: Effective within a wide range of pressures and temperatures. For instance, under high-temperature and high-pressure conditions, ball valves maintain stable sealing performance.

- Reliable Bi-directional Sealing: Ensures no leakage of medium. Ball valve seats are made of elastic materials, ensuring reliable sealing on both sides.

- Low Flow Resistance: Improves fluid flow efficiency. Well-designed ball valve balls result in low fluid resistance, reducing energy consumption.

- Quick Opening and Closing: Some structures have extremely short opening and closing times, suitable for automated systems. In factories with high levels of automation, ball valves can rapidly open and close, improving production efficiency.

- High Pressure Differential Resistance: Ensures safe and stable valve operation. The structural design of ball valves can withstand high pressure differentials, suitable for high-pressure fluid pipelines.

- Automatic Positioning: The spherical closing element can automatically position at boundary positions. Through the valve's automatic positioning function, manual operations are reduced, enhancing production efficiency.

- Corrosion Resistance: Suitable for corrosive media and low-boiling-point liquids. Ball valves are made of corrosion-resistant materials, capable of long-term stable operation in harsh working environments.

Top-entry ball valves play an irreplaceable role in industrial production with their simple structure, superior performance, and wide applications, providing significant assurance for industrial production. In the future, with the continuous development of industrial technology, top-entry ball valves will continue to play an important role and demonstrate their value in more fields.

Next: Resolving Common Issues of Forged Steel Gate Valves

Previous: Trunnion Mounted Ball Valves: Common Problems and Solutions

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China